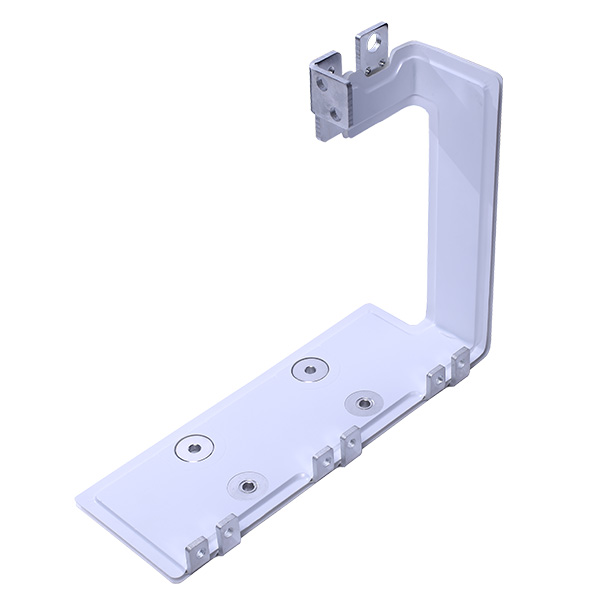

Laminated Busbar / Multi-layer Busbar for Inverter

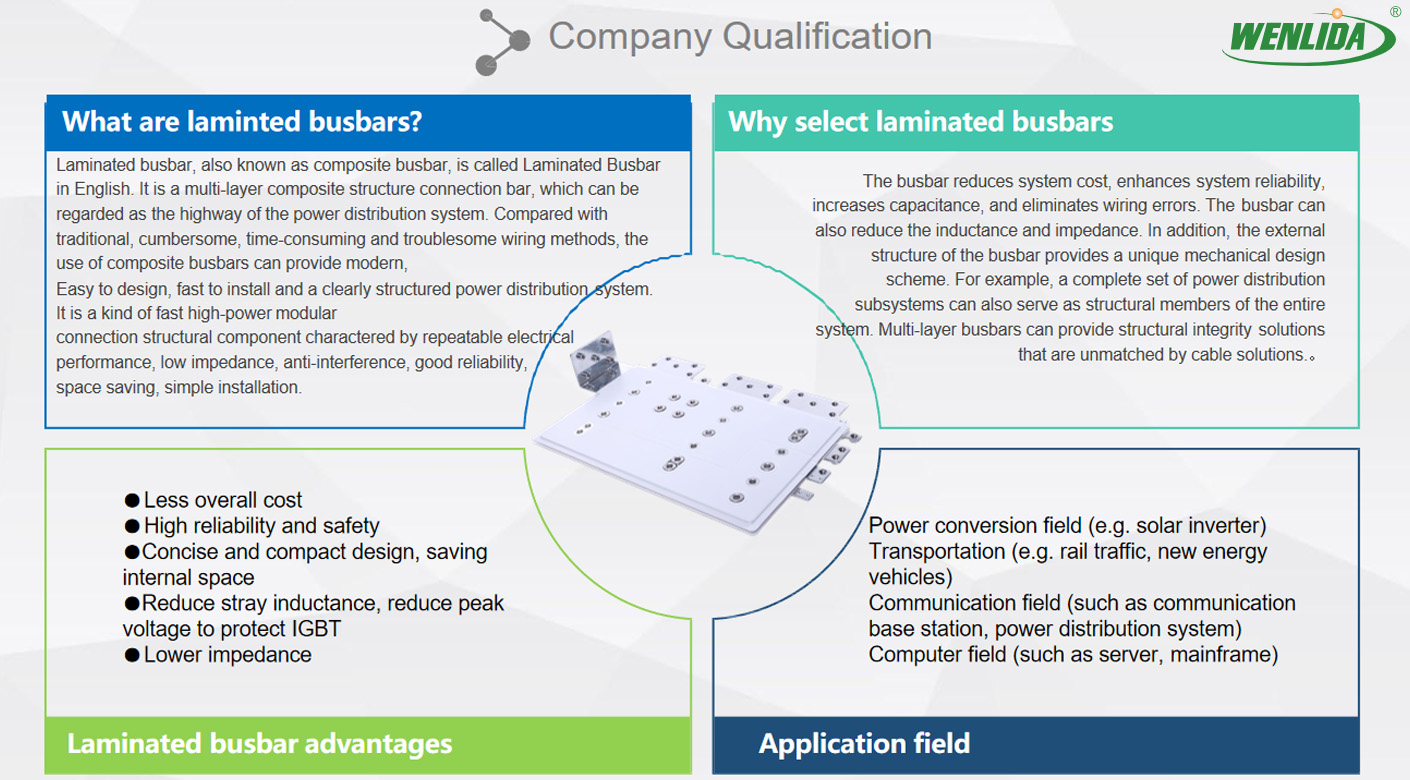

Laminated busbar, also known as a composite busbar, is called a Laminated Busbar in English. It is a multi-layer composite structure connection bar, which can be regarded as the highway of the power distribution system. Compared with traditional, cumbersome, time-consuming and troublesome wiring methods, the use of composite busbars can provide a modern, easy-to-design, fast-to-install and clearly structured power distribution system.

- Insulation voltage:300V-20KV

- Rated current:0-4000A

- Insulation resistance:20M Ω- infinity

- Temperature rise:<40K

Product Description

A multi-layer busbar is a component used in the construction of inverters, particularly in power electronic systems. Inverters are devices that convert direct current (DC) into alternating current (AC). They are commonly used in various applications such as solar power systems, wind power systems, motor drives, and uninterruptible power supplies (UPS).

Advantages

- Conductivity and Low Resistance: Multi-layer busbars are designed to have high electrical conductivity, minimizing resistive losses and ensuring efficient power transmission.

- Compact Design: The multi-layer configuration allows for a compact design, optimizing the use of space within the inverter.

- Heat Dissipation: Efficient heat dissipation is crucial in power electronic systems. Multi-layer busbars are often designed to facilitate the transfer of heat away from critical components, contributing to the overall thermal management of the inverter.

- High Current-Carrying Capacity: Inverters handle significant amounts of electrical current. Multi-layer busbars are engineered to have a high current-carrying capacity, ensuring they can handle the power demands of the system.

- Reliability: Reliability is essential in power electronics. Multi-layer busbars are constructed with materials and designs that enhance their reliability, contributing to the overall robustness of the inverter.

Technical Parameter

| Busbar | |

| Item | Illustration |

| Conductor material | T2 red copper, 1060AL, copper cladding aluminum |

| Insulation voltage | 300V-20KV |

| Rated current | 0-4000A |

| Connection type | Copper plate embossing, copper pillar riveting, copper pillar welding |

| Duct surface treatment | Passivation, tin plating, nickel plating, silver plating, conductive oxidation |

| Insulation material | PET,PI,FR4,Insulating powder,GPO3 |

| Flammability rating | UL 94V-0 |

| Insulation resistance | 20M Ω-

infinity |

| Temperature rise | <40K |

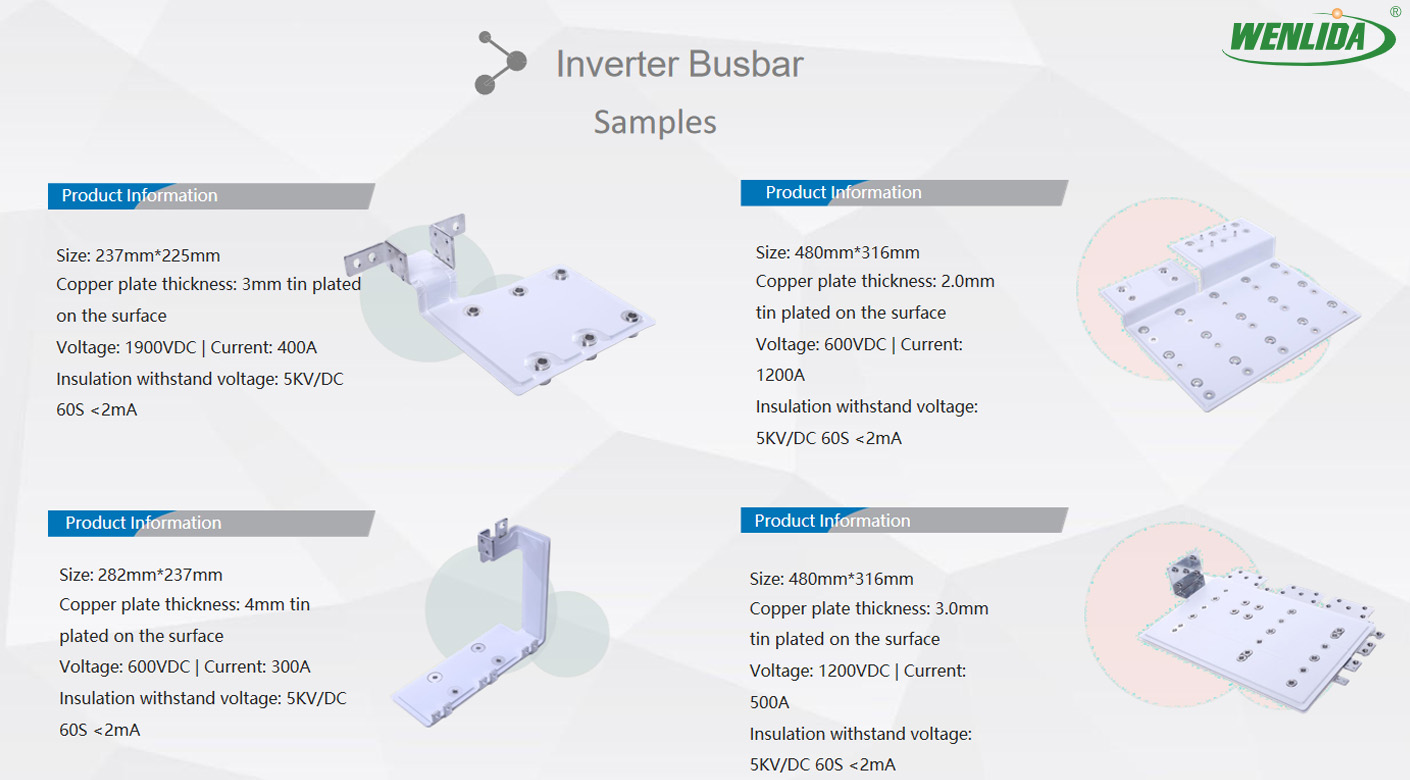

Product Data

| Busbar | |||

| Item | Instruction | ||

| Max. layer No.s | 6 | Surfuce treatment | Nickel plating, tin plating, silver plating, gold plating, passivation, anodizing |

| Temperature rise | ≤30K | Interlayer adhesion | >1300N (Splitting strength) |

| Max.size | 1000MM*1800MM | Insulation material | NOMEX、PI、PVF、PET |

| Working temperature | -40~105℃ | Local discharge | <10PC |

| Max voltage withstanding range | 1000~20KV | Parasitic inductance | 15nH/m |

| Insulation resistance | 20M Ω DC/1000V | Production capacity | 20000pieces/month |

| Delivery time | 2 weeks ~3 three weeks | Bulk delivery time | Within the first batch of 100 tablets / 3 weeks, the rest will be distributed in batches |

Insulation material data

| Material property | Density (g/cm3) | Thermal expansion coefficient | Thermal conductivity yW (kg.K) | Dielectric constant (f=60 Hz) | Dielectric strength (kV/mm) | Flame retardant grade | Insulation heat resistance grade | Water absorption (%)/24h |

| NOMEX | 0.8~1.1 | 0.143 | 1.2 | 9 | 94 V-0 | 220 | ||

| PI | 1.42 | 20 | 0.094 | 3.7 | 9 | 94 V-0 | 220 | 0.24 |

| PVF | 1.38 | 53 | 0.126 | 10.4 | 19.7 | 94 V-0 | 105 | 0 |

| PET | 1.38~1.41 | 60 | 0.128 | 3.3 | 25.6 | 94 V-0 | 120 | 0.1-0.2 |

| FR4 | 1.32 | 45~65 | 0.18 | 4.4 | 15.7 | 94 V-0 | 155 | 0.1 |

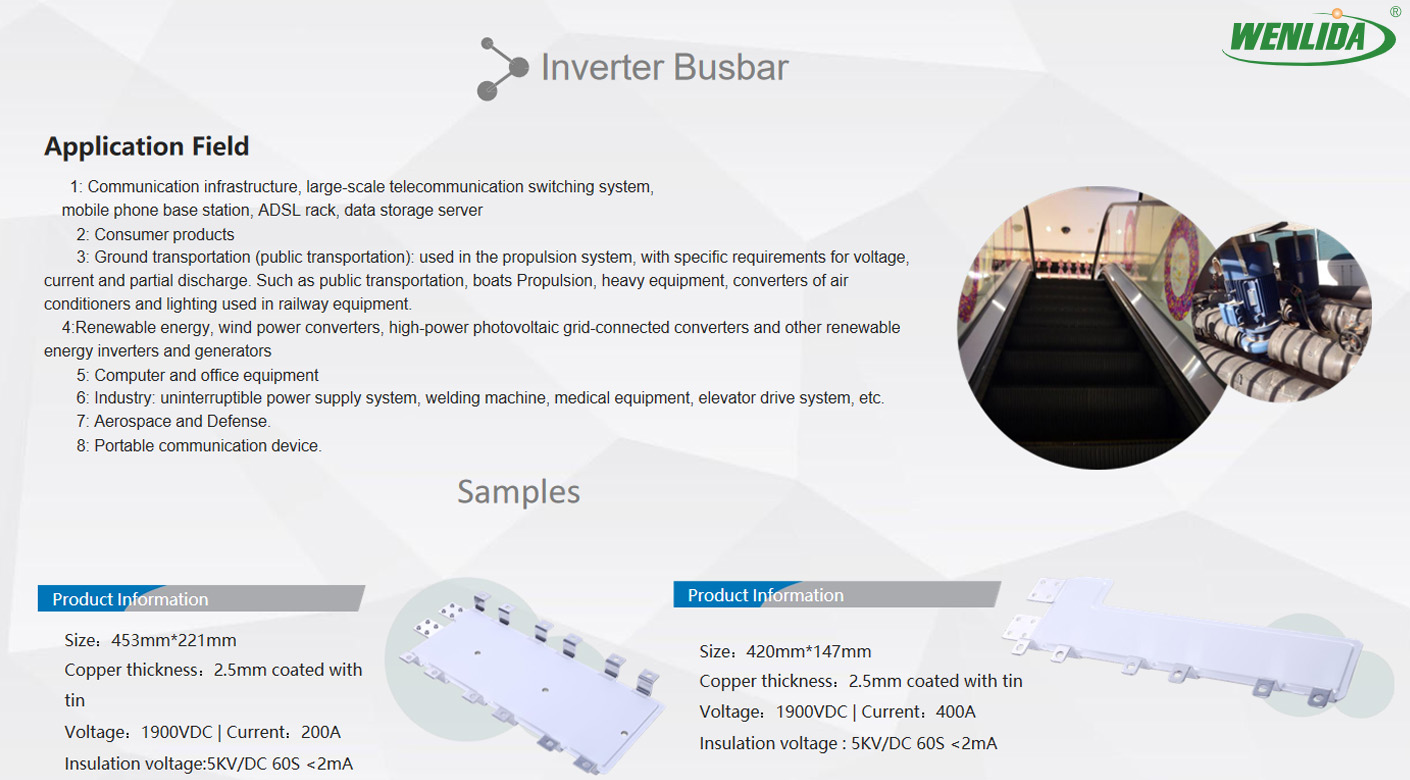

Application Fields

-

- Inverters can be found in various consumer products, such as household electronics and appliances, where they are used to convert DC power to AC power. Multi-layer busbars might be utilized for compact and efficient power distribution within these devices.

- Inverters play a crucial role in the propulsion systems of public transportation vehicles, boats, heavy equipment, and converters used in railway equipment. The specific voltage, current, and partial discharge requirements highlight the need for customized and reliable power electronics solutions, potentially incorporating multi-layer busbars.

- Inverters are a key component in renewable energy systems, including wind power converters and high-power photovoltaic grid-connected converters. Multi-layer busbars could be integrated to enhance power transmission efficiency and thermal management in these applications.

- Inverters are used in computers and office equipment to ensure the proper functioning of power-sensitive components. Multi-layer busbars may be employed for effective power distribution and heat dissipation in these devices.

- Inverters are utilized in various industrial applications such as uninterruptible power supply systems, welding machines, medical equipment, and elevator drive systems. Multi-layer busbars could be integrated to meet high current-carrying capacity requirements and ensure reliable power distribution.

- Inverters find applications in aerospace and defense systems for various power conversion needs. Multi-layer busbars may be used to address space constraints and enhance the overall reliability of power distribution in these critical applications.

- Inverters are used in portable communication devices to convert and manage power efficiently. Multi-layer busbars may be incorporated to optimize space utilization and improve the overall performance of these compact devices.

Recommend

Now, let your business to a higher level, start professional consultation!

*We Will Reply To You Within 24 hours. Our working days are Mon.to Sat., 9:00 ~ 18:00.