What Makes Laminated Busbar in Railways Power Distribution?

In recent years, the laminated busbar market, especially in rail transportation, has seen impressive growth. In 2023, the market size for laminated busbars in the transport sector was valued at approximately USD 1.5 billion, with a compound annual growth rate (CAGR) of 6.8%. This surge in demand is primarily driven by the rapid electrification of rail networks, as well as the growing need for more efficient and reliable power distribution solutions to support modern rail vehicles.

As countries around the world continue to invest in electrified rail systems, the demand for Laminated Busbar in Railways—known for their efficiency in high-current applications—has intensified. Looking ahead, industry analysts predict that the market will expand further, reaching USD 2.5 billion by 2030. This growth is not only fueled by the electrification of railways but also by the increasing adoption of electric vehicles (EVs), which also rely on laminated busbars for efficient power management in various applications.

Key Advantages of Laminated Busbars in Rail Systems

High Current Capacity and Efficiency

Laminated busbars are designed to manage high currents with remarkable efficiency. Copper, known for its excellent electrical conductivity, ensures that power loss and heat generation are minimized. This makes laminated busbars ideal for use in rail vehicles, where consistent and reliable power delivery is essential to drive traction motors, lighting systems, and other electrical components.

Space-Saving Design

Space is often a luxury in rail vehicle design. Laminated busbars for rail offer a compact solution without compromising electrical performance. The multi-layer construction not only provides a rugged and durable power distribution system, but also ensures that rail vehicles, especially high-speed trains and urban rail systems, can maximize the use of available space – a critical factor in today’s track design.

Durability and Reliability

Built to withstand harsh operating conditions, laminated busbars are highly durable, and resistant to vibrations, temperature fluctuations, and mechanical stress. Their mechanical strength, coupled with high electrical efficiency, ensures that they perform reliably even in the demanding environments found in rail systems.

Faster Installation and Reduced Costs

Compared to traditional cabling systems. One of the main advantages of laminated busbars is the reduction in installation time and associated labor costs. These busbars are prefabricated in customizable configurations. Can be quickly integrated into rolling stock, significantly reducing assembly time and minimizing labor requirements. This not only cuts costs but also allows manufacturers to maintain high-quality standards.

Versatile Applications of Laminated Busbars in Railway Power Systems

Laminated Busbar in Railways serve a wide range of functions in the power distribution systems of rail vehicles, offering flexible solutions for various needs.

Traction Power Distribution

Laminated busbars are crucial in distributing electrical power from the source to the traction motors in electric trains. They ensure that the necessary high currents are delivered efficiently, allowing the train to operate at optimal performance levels and maintain speed without compromising power integrity.

Power for Control Systems

In addition to powering the traction motor. Laminated busbars are also used to power important control systems such as signaling and communications equipment. Their low impedance and anti-interference properties ensure that electrical systems continue to operate smoothly even in environments prone to electrical noise.

Lighting and HVAC Power Distribution

Laminated busbars also play a role in supplying power to the lighting and HVAC systems within rail vehicles. These systems, which are essential for passenger comfort and safety, require a steady, reliable power supply to function optimally throughout a journey.

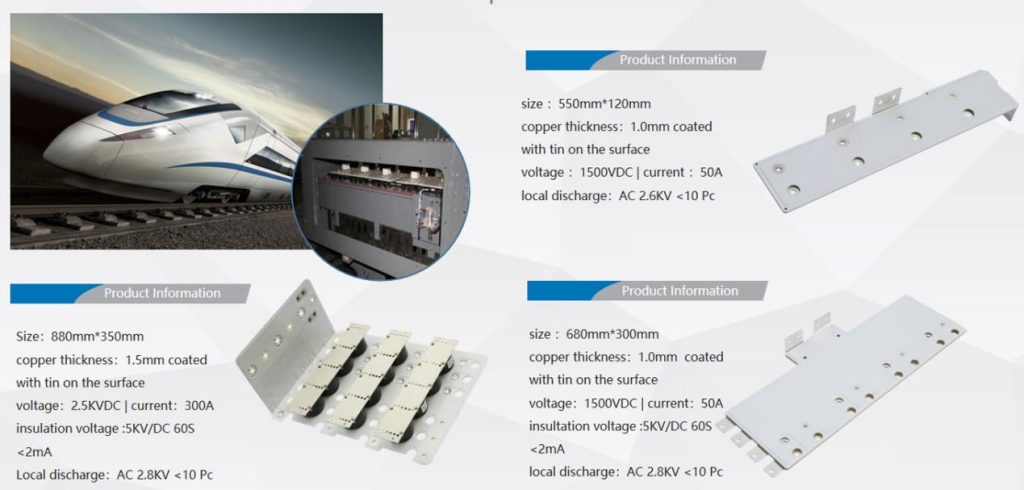

Shanghai Wenlida Technology Co., Ltd.: A Key Supplier in the Laminated Busbar Market

As the demand for high-performance laminated busbars in rail transportation continues to rise, manufacturers like Shanghai Wenlida Technology Co., Ltd. are stepping in to provide advanced, high-quality solutions designed to meet the ever-evolving needs of the industry. Wenlida specializes in the production of laminated copper busbars for a wide range of applications such as railways. It has firmly established its leading position in the global market. Their expertise in busbar design and manufacturing ensures that the products they provide are highly customized. To meet the unique challenges and requirements of modern railway operators.

Wenlida railway laminated busbars have excellent conductivity, durability and thermal efficiency. They are well suited for the harsh environment of rail vehicles. These busbars are manufactured to strict industry standards. Ensure that they can withstand the mechanical stress, temperature fluctuations and vibrations common in rail transportation. Moreover, they are designed for ease of installation and reduced maintenance, offering operators a reliable and cost-effective power distribution solution.

Shanghai Wenlida Technology Co., Ltd. is committed to continuous innovation and high-quality manufacturing. By supplying railway laminated busbars, it ensures the safety, efficiency and reliability of rail vehicle electrical systems, and plays a key role in the development of the railway industry. It has contributed to the development of modern electrified transportation networks around the world.

Emerging Trends and Future Needs in the Laminated Busbar Market

Looking towards the future, the Laminated Busbar in Railways market in the rail sector is set for sustained growth. The global push towards more sustainable, energy-efficient transportation solutions is accelerating the adoption of electric and hybrid trains. As rail networks continue to electrify, the demand for efficient power distribution systems will increase, driving the need for laminated busbars.

Several trends are expected to shape the laminated busbar market in the coming years:

Electrification of Rail Networks: As more and more countries embark on electrified railway system projects. The demand for laminated busbars will also grow accordingly.

Technological Advancements: Continued innovation in materials and designs will result in more efficient, more compact, and more versatile laminated busbars. Further expand its role in modern railway systems.

Focus on Cost-Efficiency:As manufacturers and operators aim to reduce operating costs, laminated busbars offer a cost-effective solution. Minimizes installation time, space usage and long-term maintenance.

Conclusion: The Increasing Importance of Laminated Busbars in Rail Transport

Laminated busbars for railways have become an integral part of the railway industry due to their numerous advantages, including high electrical efficiency, space optimization, and ease of installation. As railway electrification continues to expand and the need for reliable power systems continues to increase. Laminated busbars will play an even more critical role in shaping the future of modern rail transport. With industry leaders like Shanghai Wenlida Technology Co., Ltd. continuing to innovate, laminated busbars will remain a key solution for developing efficient, reliable, and high-performance rail networks worldwide.