Laminated Busbar in Railways: Here to Know

Laminated busbars are integral to the electrical systems of railways, serving as efficient conductors that distribute power from sources to essential components like traction motors and control systems within trains. Constructed from multiple layers of copper sheets separated by insulating materials, these busbars optimize space utilization while ensuring robust electrical performance. Their design not only minimizes energy losses but also facilitates quick installation and maintenance, contributing to the overall reliability and operational efficiency of modern rail networks.

What is Laminated Busbar in Railways

In the realm of railway transportation, the Laminated Busbar in Railways plays a pivotal role in ensuring the efficient and reliable distribution of electrical power throughout rail vehicles. This specialized component is constructed from multiple layers of thin copper sheets interleaved with insulating materials, forming a robust structure capable of handling high currents and voltages while occupying minimal space.

Railway systems rely heavily on electric power for propulsion, lighting, HVAC systems, and various control mechanisms. The laminated busbar serves as a crucial conduit, transmitting power from the main sources to these critical systems. Its design not only enhances electrical conductivity but also minimizes losses, contributing to the overall energy efficiency of the railway infrastructure.

Meeting the Unique Needs of Railway Electrification

Railway electrification demands solutions that can handle high currents, minimize space requirements, and ensure continuous operation under varying environmental conditions. Laminated Busbar in Railways from Shanghai Wenlida Technology Co., Ltd. excels in these areas by virtue of their compact yet robust construction. By utilizing multiple layers of copper and insulation, these busbars reduce inductance and impedance, thereby improving electrical efficiency and reducing power losses. This design approach not only enhances the reliability of electrical connections but also contributes to the longevity of onboard systems.

Moreover, the mechanical design of laminated busbars serves a dual purpose in railway applications. Beyond their electrical function, these busbars can be integrated structurally within the vehicle, providing additional support and reducing the need for separate structural components. This integration capability not only streamlines assembly processes but also enhances the overall mechanical integrity of the rolling stock.

Advantages of Laminated Busbars in Railway Applications

One of the standout features of laminated busbars in railway applications is their compact design. Unlike traditional busbars, which often require more space due to their bulkier construction, laminated busbars can be customized to fit into confined spaces within rail vehicles. This space efficiency is particularly advantageous in modern trains where maximizing passenger or cargo space is a priority.

Moreover, the modular nature of laminated busbars facilitates easier installation and maintenance. Pre-manufactured units can be quickly integrated into the electrical system during assembly, reducing both labor costs and assembly time. This efficiency not only streamlines production processes but also ensures quicker turnaround times for rolling stock deployment and maintenance.

Technical Capabilities and Performance Enhancements

Laminated busbars are engineered to deliver superior electrical performance compared to conventional busbar designs. By using multiple layers of copper separated by insulating materials, these busbars effectively manage current distribution while mitigating the risk of electrical faults such as short circuits. This enhanced reliability is crucial for maintaining uninterrupted operation and safety in railway environments.

Furthermore, the design flexibility of Laminated Busbar in Railways allows for the incorporation of signal acquisition points at various locations along the busbar. These points enable real-time monitoring and diagnostics of electrical parameters, enhancing the overall control and maintenance capabilities of railway systems. Operators can promptly identify and address issues, thereby improving reliability and reducing downtime.

Application and Product Examples

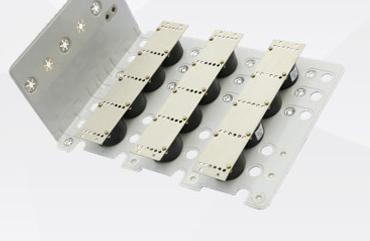

Shanghai Wenlida Technology Co., Ltd., a leading supplier in the field, offers a range of laminated busbars tailored specifically for railway applications. These products exemplify the versatility and technical prowess required to meet the stringent demands of modern rail transportation systems.

Sample Product Information 1

Size: 550mm * 120mm

Copper Thickness: 1.0mm, coated with tin

Voltage: 1500V DC

Current: 50A

Local Discharge: AC 2.6KV <10 Pc

Sample Product Information 2

Size: 880mm * 350mm

Copper Thickness: 1.5mm, coated with tin

Voltage: 2.5KV DC

Current: 300A

Insulation Voltage: 5KV DC, 60S <2mA

Local Discharge: AC 2.8KV <10 Pc

Sample Product Information 3

Size: 680mm * 300mm

Copper Thickness: 1.0mm, coated with tin

Voltage: 1500V DC

Current: 50A

Insulation Voltage: 5KV DC, 60S <2mA

Local Discharge: AC 2.8KV <10 Pc

These product specifications highlight the diverse configurations available to cater to different voltage and current requirements within railway systems. Each unit is meticulously crafted to ensure optimal performance and longevity under demanding operational conditions, reflecting the commitment to quality and innovation in railway electrification technologies.

Future Trends and Innovations in Railway Electrification

Looking ahead, the evolution of laminated busbar technology is poised to align with broader trends in railway electrification. As railways increasingly transition towards electrified and hybrid propulsion systems, the demand for efficient power distribution solutions will intensify. Innovations in materials, such as advanced composites and coatings, may further enhance the performance and reliability of laminated busbars, offering potential improvements in energy efficiency and environmental sustainability.

Moreover, integration with digital monitoring and control systems will continue to play a crucial role in optimizing railway operations. Enhanced data acquisition capabilities through smart busbar designs will enable predictive maintenance strategies, reducing downtime and enhancing overall service reliability. These advancements underscore the pivotal role of laminated busbars not only in current railway infrastructure but also in shaping the future of sustainable and efficient rail transportation worldwide.

Advancing Railway Electrification with Shanghai Wenlida Technology Co., Ltd.

Expertise and Experience in Power Quality Solutions

With over 28 years of experience and more than 20 production lines, Shanghai Wenlida Technology Co., Ltd., excels in developing and manufacturing a wide array of power quality equipment. This includes industrial voltage stabilizers, high and low voltage reactive power compensation devices, harmonic filtering devices, and, notably, laminated busbars. These products cater to various industries such as rail transit, electric power, telecommunications, and new energy sectors globally.

Application of Laminated Busbars in Railway Systems

Laminated busbars manufactured by Shanghai Wenlida Technology Co., Ltd., play a pivotal role in advancing railway electrification projects worldwide. These busbars are designed to optimize power distribution efficiency while minimizing space requirements and installation complexity. In railway applications, where reliability and safety are paramount, these busbars offer distinct advantages over traditional wiring solutions.

By integrating multiple functions into a compact and robust design, laminated busbars reduce system costs and enhance operational reliability. They mitigate the risks associated with wiring errors and reduce maintenance downtime, thereby ensuring an uninterrupted power supply essential for modern railway operations. Moreover, their ability to minimize inductance and impedance contributes to improved energy efficiency, supporting sustainable transportation initiatives globally.

Conclusion

In conclusion, laminated busbars represent a cornerstone technology in the electrification of railways, providing essential electrical connectivity with enhanced efficiency and reliability. Their compact design, superior performance characteristics, and adaptability to varying operational requirements make them indispensable components within modern rail vehicles. As the industry evolves, innovations in laminated busbar technology are expected to drive significant advancements in railway electrification, supporting the transition towards cleaner and more sustainable transportation solutions globally.