The Cost-Effectiveness of Laminated Busbar in Photovoltaic Power Generation Solutions

Introduction to Laminated Busbars

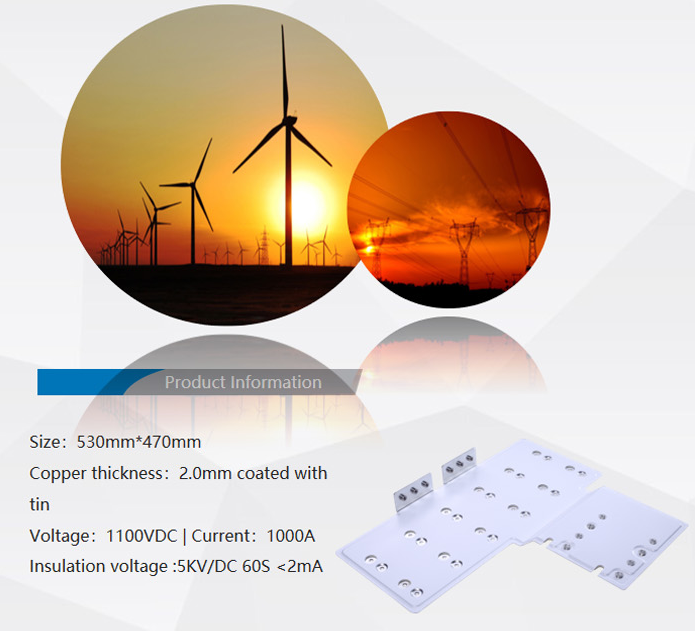

In the swiftly transforming landscape of renewable energy, the importance of efficiency and dependability cannot be overstated. Laminated Busbar in Photovoltaic Power Generation have surfaced as essential elements within photovoltaic (PV) power generation frameworks. Comprising multiple layers of conductive and insulating materials, these innovative conductors not only enhance overall performance but also tackle prevalent challenges associated with solar energy distribution. Given the rising demand for sustainable energy solutions, gaining a comprehensive understanding of the roles and benefits of laminated busbars can profoundly influence project success.

The Basics of Laminated Busbars

Laminated busbars function as crucial connectors in electrical power distribution networks. Their design features several layers that effectively minimize electrical losses while enhancing thermal management. The combination of conductive and insulating materials results in a solution that is both lightweight and robust, enabling it to endure harsh environmental conditions. This durability makes Laminated Busbar in Photovoltaic Power Generation particularly suitable for solar energy applications, where both reliability and efficiency are of the essence.

In large-scale solar farms, laminated busbars prove invaluable by managing the considerable power output generated by numerous solar panels. By facilitating efficient power distribution, these busbars contribute to the overall effectiveness of photovoltaic systems, ensuring that the energy produced is transmitted to inverters and ultimately fed into the grid.

Advantages of Laminated Busbar in Photovoltaic Power Generation

Reliability and Performance

Laminated Busbar in Photovoltaic Power Generation is celebrated for its reliability. A key advantage lies in their low inductance, which significantly reduces energy losses and bolsters overall system efficiency—an essential feature in PV systems where each watt generated holds substantial importance. Furthermore, these busbars adeptly manage partial discharge, a frequent issue in electrical systems that can lead to insulation failure and a diminished lifespan.

Another significant advantage is their optimized characteristics regarding heat resistance. In solar applications, various components are often subjected to extreme temperatures. Laminated busbars are designed to function effectively within a temperature spectrum of -40°C to 105°C, thus ensuring stable performance across fluctuating conditions. Moreover, their enhanced electromagnetic interference shielding reduces disruptions in power distribution, further cementing their role in reliable energy systems.

Cost-Effectiveness of Installation

From an economic standpoint, laminated busbars yield considerable savings during installation. Their compact design not only conserves space but also simplifies the installation process, leading to decreased labor expenses. The design features that minimize the possibility of installation errors guarantee that systems can be operational swiftly.

Durability emerges as another crucial aspect in the cost-effectiveness equation of laminated busbars. Their sturdy construction results in extended lifespans, thereby reducing the necessity for frequent replacements or maintenance. As the appetite for renewable energy continues to surge, the financial benefits of incorporating laminated busbars into PV systems become increasingly evident, making them a prudent investment for solar projects.

Insulation and Safety

The insulation resistance of Laminated Busbar in Photovoltaic Power Generation is an impressive 20 MΩ DC/1000V, ensuring safety in high-voltage scenarios. Such a high insulation level is vital in solar energy systems, where voltage levels can fluctuate considerably. This effective insulation mechanism helps prevent electrical shocks and safeguards both equipment and personnel involved in the installation and upkeep of solar power systems.

Additionally, the parasitic inductance of laminated busbars is limited to only 15 nH/m, which further enhances their reliability in electrical distribution. This low inductance minimizes power loss, ensuring that the maximum amount of generated energy is readily available for utilization. These safety features, in conjunction with the cost-effectiveness of laminated busbars, position them as a favored choice in photovoltaic power generation.

Improving Heat Dissipation in Photovoltaic Systems

Thermal Management Challenges in PV Systems

Effective thermal management is essential in the realm of photovoltaic power generation. During operation, solar panels generate heat, which, if not properly managed, can adversely affect efficiency. Laminated Busbar in Photovoltaic Power Generation plays a pivotal role in facilitating heat dissipation, thereby helping to maintain optimal operating temperatures within the system. By improving heat resistance and establishing efficient thermal pathways, these busbars alleviate the risks associated with overheating.

When photovoltaic systems reach elevated temperatures, they can experience reduced efficiency and shortened lifespans. Laminated busbars tackle this issue by dissipating heat effectively, ensuring that energy loss due to thermal buildup is kept to a minimum. This is particularly critical in expansive solar installations, where the cumulative impact of heat can lead to significant efficiency declines.

Design Innovations in Laminated Busbars

The design of Laminated Busbar in Photovoltaic Power Generation has been specifically engineered to enhance thermal management capabilities. Their layered construction allows for superior heat dissipation when compared to traditional busbars, which may struggle to perform under high thermal loads. The integration of various materials within the laminate structure enables these busbars to endure higher temperatures without sacrificing performance.

Moreover, the lightweight nature of laminated busbars further contributes to improved heat dissipation. Their reduced weight facilitates easier installation and integration into existing systems, while their efficient design ensures that heat generated during operation is effectively managed. This culminates in longer-lasting systems and an overall enhancement in performance.

Real-World Applications of Laminated Busbars

Laminated busbars are increasingly being adopted in a diverse array of photovoltaic projects worldwide. From extensive solar farms to residential installations, these components are demonstrating their value in improving efficiency and reliability. Prominent projects have showcased the efficacy of laminated busbars in managing thermal loads and optimizing energy distribution.

For instance, in a recent large-scale solar project, the incorporation of laminated busbars resulted in a notable increase in energy output by ensuring effective heat dissipation and dependable power distribution. Such successes have led more developers to consider laminated busbars as standard components in their photovoltaic systems, underscoring their effectiveness in practical applications.

From Concept to Reality: Laminated Busbars in Sustainable Energy Solutions

The Evolution of Busbar Technology

The concept surrounding laminated busbars in photovoltaic systems has undergone significant evolution over the years. Initially regarded as a niche solution, these components have garnered widespread acclaim for their efficiency and reliability advantages. As the demand for renewable energy escalates, innovations in Laminated Busbar in Photovoltaic Power Generation technology continue to propel their adoption within solar applications.

Manufacturers such as Shanghai Wenlida Technology Co., Ltd. are spearheading this evolution by developing advanced laminated busbar designs that address the unique challenges posed by solar energy distribution. By emphasizing innovation and performance, these suppliers are instrumental in shaping the future of photovoltaic systems.

Industry Standards and Compliance

With the increasing popularity of laminated busbars, the importance of industry standards and compliance measures has also risen. Ensuring that these components meet safety and performance regulations is crucial for preserving system integrity and reliability. The application of rigorous testing and quality control protocols serves to guarantee that laminated busbars function as expected in real-world scenarios.

Compliance with industry standards also reassures developers and investors, providing confidence that the components utilized in their solar projects are both reliable and safe. This commitment to quality and adherence to regulations is fundamental in fostering trust within the renewable energy sector.

Future Prospects for Laminated Busbars

Looking toward the future, the outlook for laminated busbars in photovoltaic power generation is exceptionally promising. As technology progresses and the demand for sustainable energy solutions intensifies, the significance of these components will only grow. Continuous research and development endeavors aim to further enhance the performance and efficiency of laminated busbars, rendering them even more integral to solar power systems.

With an increasing focus on energy efficiency and sustainability, laminated busbars are poised to play a crucial role in the global transition to renewable energy. As the industry continues to evolve, these components will remain a central focus for innovation, driving advancements in photovoltaic power generation and contributing to a more sustainable future.

Conclusion

In summary, Laminated Busbar in Photovoltaic Power Generation stands as a formidable solution within the realm of photovoltaic power generation. Their reliability, cost-effectiveness, and thermal management capabilities render them indispensable in contemporary solar applications. As the industry progresses, the integration of laminated busbars is sure to facilitate the ongoing growth and success of renewable energy solutions on a global scale.