Improving Efficiency and Quality: Active Power Filters in Industrial Settings

In the bustling landscape of industrial operations, efficiency and quality are paramount. Any disruptions or inefficiencies can lead to significant losses in productivity and resources. One critical aspect often overlooked is the management of power quality, especially in facilities where sensitive equipment operates alongside heavy machinery. This is where Active Power Filters (APFs) come into play, offering a robust solution to mitigate power quality issues and optimize operations. Let’s delve into a case study where APFs revolutionized the power management system of a chemical fiber factory, transforming its efficiency and productivity.

Understanding the Essence of Active Power Filters

1. Dynamic Harmonic Suppression

At the core of APF’s functionality lies its ability to detect load current, extract harmonic components, and generate harmonic currents in opposite phases to neutralize undesirable harmonics. This process is orchestrated through sophisticated algorithms and controlled by Insulated Gate Bipolar Transistors (IGBTs), ensuring precise harmonic filtering.

2. Versatile Reactive Power Compensation

Beyond harmonics, APFs offer a versatile solution for reactive power compensation. By seamlessly switching between capacitive and inductive reactive power, they optimize power factors and mitigate voltage fluctuations, bolstering the stability and efficiency of electrical networks.

Advantages Galore: Unraveling the Benefits of APFs

1. Comprehensive Power Quality Enhancement

APFs present a multifaceted approach to power quality enhancement, encompassing harmonic control, reactive power compensation, and three-phase imbalance correction. This holistic functionality ensures optimal performance and reliability in diverse operational scenarios.

2. Exceptional Performance Metrics

With response times of less than 10 milliseconds and Total Harmonic Distortion (THD) below 5%, APFs deliver unparalleled performance. Achieving Power Factors (PF) exceeding 98% and maintaining a three-phase imbalance below 3%, they set new benchmarks for efficiency and reliability in power management.

3. Flexible Harmonic Filtering

Flexibility is a hallmark of APFs, as they effectively filter harmonics ranging from the 2nd to the 50th order. This granular control empowers users to target specific harmonic frequencies, customizing filtration to suit unique requirements and optimizing performance.

The Challenge: Power Quality Issues in a Chemical Fiber Factory

In the heart of a chemical fiber factory, power quality issues were causing a cascade of problems. The factory relied on a combination of power frequency supply and medium frequency heating equipment to fuel its operations. However, the harmony between these systems was disrupted by voltage and current harmonics exceeding standards. This led to a deterioration in product quality and reduced yield, hitting the bottom line hard.

Moreover, the existing compensating cabinet suffered severe damage due to these power quality issues. Overheating became a common occurrence, plaguing crucial components like copper bars and transformers. The repercussions were dire, with increased downtime, maintenance costs, and a significant dent in profitability.

The Solution: Implementing Active Power Filters

Recognizing the urgency of the situation, the management turned to Wenlida, a reputable manufacturer of Active Power Filters. After careful assessment and consultation, the decision was made to install two sets of 150A APFs alongside the existing 1600 kVA transformer.

The implementation of APFs promised a comprehensive solution to the power quality woes plaguing the factory. By actively filtering out harmonics and other disturbances, APFs could restore the balance and stability required for seamless operations.

The Results: Transformative Impact on Efficiency and Reliability

The results of implementing APFs were nothing short of transformative. With the active filtering capabilities of APFs in place, the factory witnessed a remarkable improvement in power quality metrics. Total Harmonic Distortion in voltage (THDU) was reduced to less than 5%, and THD in current (THD|) also plummeted below 5%.

Additionally, the power factor surged past 0.95, a testament to the enhanced efficiency of the power management system. The once prevalent weak current disturbances became a thing of the past, paving the way for smoother operations.

One of the most significant benefits was the drastic reduction in damage rates, especially concerning the inverter. With APFs mitigating harmful harmonics and fluctuations, the damage rate plummeted by a staggering 90%. This not only saved on repair and replacement costs but also minimized downtime, ensuring uninterrupted production schedules.

Furthermore, the threat of overheating, which loomed large over copper bars and transformers, was significantly alleviated. The implementation of APFs led to a noticeable reduction in temperature fluctuations, safeguarding critical components and prolonging their lifespan.

Step 1: Assessing Power Quality Needs

Before embarking on the journey to purchase an APF, it’s imperative to assess the specific power quality requirements of your facility or operation. Conduct a comprehensive analysis of your electrical system, identifying potential harmonic distortions, reactive power issues, and voltage fluctuations. By understanding the unique challenges faced by your infrastructure, you can determine the precise capabilities and specifications needed in an APF to address these concerns effectively.

Step 2: Researching Available Solutions

With a clear understanding of your power quality needs, the next step is to research available APF solutions in the market. Begin by exploring reputable manufacturers like Wenlida, known for their expertise and innovation in power filtration technology. Evaluate product specifications, performance metrics, and customer reviews to discern which APF aligns best with your requirements. Consider factors such as harmonic filtering range, reactive power compensation capabilities, response time, and system compatibility to narrow down your options effectively.

Step 3: Engaging with Manufacturers

Once you’ve identified potential APF solutions, it’s time to engage directly with manufacturers to gather more information and clarify any queries. Reach out to Wenlida through their designated contact channels, such as export@wenlida.com or by phone at +86-21-31160606. Discuss your power quality challenges and requirements in detail, seeking expert guidance from their knowledgeable team. Utilize this opportunity to inquire about product features, customization options, pricing, and lead times, ensuring a comprehensive understanding of the APF procurement process.

Step 4: Requesting Quotations and Proposals

Armed with insights from manufacturer consultations, request formal quotations and proposals from Wenlida or other selected suppliers. Provide detailed specifications and requirements to facilitate accurate pricing and proposal development. Evaluate the proposed solutions based on factors such as cost-effectiveness, technical feasibility, and alignment with your power quality objectives. Consider negotiating terms and exploring potential discounts or incentives to optimize the value proposition of your APF investment.

Step 5: Conducting Site Surveys and Assessments

Before finalizing the purchase, consider conducting site surveys and assessments in collaboration with the chosen manufacturer. This step allows for a thorough evaluation of your facility’s electrical infrastructure, confirming compatibility and optimal placement of the APF within the system. Work closely with Wenlida’s technical experts to identify potential installation challenges, determine required modifications, and develop an implementation plan that minimizes downtime and disruption to operations.

Step 6: Finalizing the Purchase and Installation

With all preparatory steps completed, it’s time to finalize the purchase agreement and proceed with the installation of the APF. Review the terms and conditions outlined in the contract provided by Wenlida, ensuring clarity and alignment with your expectations. Coordinate logistics, delivery schedules, and installation timelines with the manufacturer to streamline the implementation process. Leverage their expertise and support to oversee the successful integration of the APF into your electrical network, maximizing its effectiveness in improving power quality and efficiency.

Step 7: Post-Installation Support and Maintenance

Beyond installation, ongoing support and maintenance are essential to maximize the lifespan and performance of your APF. Partner with Wenlida for comprehensive post-installation support, including training for personnel, troubleshooting assistance, and regular maintenance services. Establish a proactive maintenance schedule to ensure optimal operation and minimize the risk of downtime or malfunctions. By prioritizing continuous support and collaboration with the manufacturer, you can reap the full benefits of your APF investment for years to come.

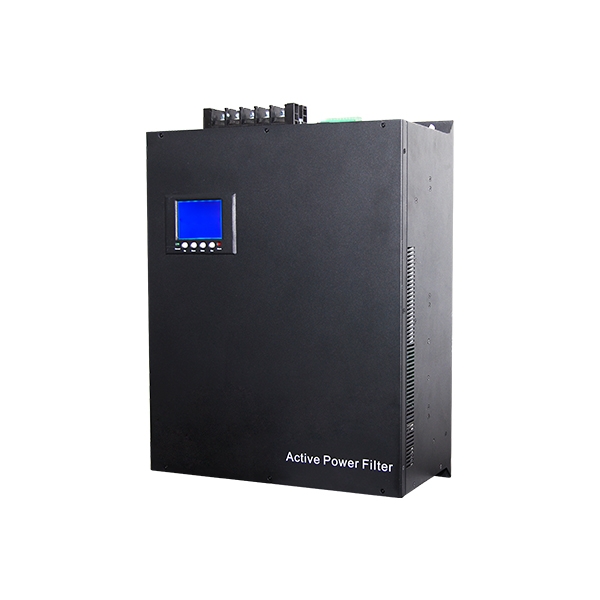

Wenlida: Leading the Charge in APF Technology

1. Innovative Design and Engineering

Wenlida stands at the forefront of APF technology, leveraging innovative design and engineering prowess to develop state-of-the-art solutions. Their commitment to excellence is evident in the modular design of APFs, which prioritizes user convenience, easy maintenance, and seamless integration into existing infrastructure.

2. Robust Protective Framework

Safety and reliability are paramount in power management, and Wenlida ensures both with a comprehensive suite of 16 protection functions embedded within APFs. This robust protective framework safeguards equipment and systems against potential risks, ensuring uninterrupted operation and peace of mind for users.

3. Customer-Centric Solutions

At Wenlida, customer satisfaction reigns supreme. Their dedication to providing tailored solutions and unparalleled support sets them apart in the industry. Whether it’s through rack-mounted or wall-mounted configurations, Wenlida ensures that APFs seamlessly integrate into diverse applications, meeting the evolving needs of modern power systems.

Conclusion: Unlocking the Potential of Active Power Filters

In a world where efficiency and quality reign supreme, the role of Active Power Filters cannot be overstated. The case of the chemical fiber factory serves as a testament to the transformative impact of APFs on industrial operations. By addressing power quality issues at their root, APFs unlock a realm of possibilities, enhancing efficiency, reliability, and profitability.

As industries continue to evolve and embrace cutting-edge technologies, the demand for robust power management solutions like APFs will only grow. With manufacturers like Wenlida leading the charge, the future looks promising for businesses striving for excellence in their operations. It’s not just about managing power—it’s about empowering industries to reach new heights of success.