Copper Busbar Conductor: Revolutionize Power Distribution System

Copper busbar conductor plays a pivotal role in contemporary power distribution systems. Their multi-layer composite structure establishes them as essential components for efficiently transporting electrical power across diverse applications. Unlike conventional wiring methods, which can be laborious and inefficient, copper busbars provide a streamlined and highly effective solution. This blog delves into the wide-ranging applications, benefits, and technical specifications of copper busbar conductors, emphasizing their indispensable role in modern electrical systems.

Understanding Copper Busbar Conductor

What is Copper Busbar Conductor?

Copper busbar conductors are multi-layer composite structures designed to distribute electrical power efficiently. They are characterized by their repeatable electrical performance, low impedance, anti-interference properties, and good reliability. These features make them indispensable in applications where space saving, simple installation, and high power efficiency are paramount.

Technical Specifications

Copper busbar conductors boast impressive technical specifications:

Insulation resistance: 20M Ω DC/1000V

Parasitic inductance: 15nH/m

Temperature rise: ≤30K

Working temperature: -40~105℃

These specifications underline the robustness and efficiency of copper busbar conductors, making them suitable for a wide range of high-power applications.

Advantages of Copper Busbar Conductor in Modern Electrical Systems

Handling High Currents Efficiently

Copper is renowned for its excellent electrical conductivity, making it an ideal material for busbars. Laminated copper busbar is specifically designed to handle high currents efficiently, ensuring minimal energy loss and optimal performance. This capability is crucial in applications where large amounts of power need to be transmitted reliably.

Heat Management

One of the significant challenges in high-current applications is managing the heat generated during power transmission. The laminated structure of copper busbars helps dissipate heat effectively, preventing overheating and maintaining the integrity of the electrical system. This heat management is essential for ensuring the longevity and reliability of the busbar and the connected components.

Enhanced Performance

By efficiently managing both current and heat, laminated copper busbars enhance the overall performance of electrical systems. This superior performance translates to reduced energy consumption, lower operational costs, and improved system reliability, making copper busbars a valuable investment for any high-power application.

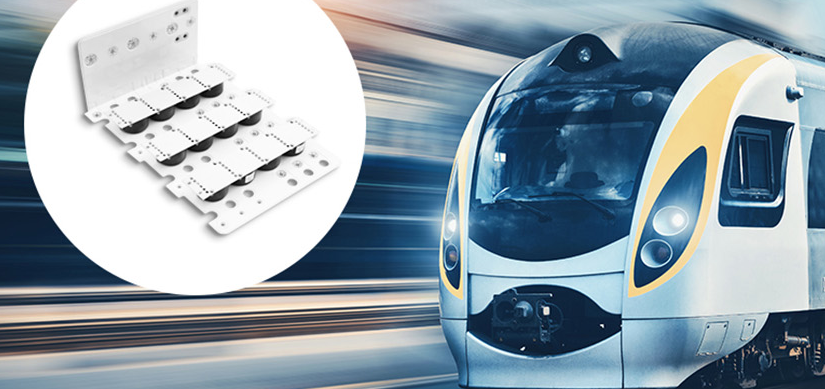

Power Distribution in Rail Transportation

Importance in Rail Systems

In rail transportation, efficient and reliable power distribution is crucial. Laminated copper busbars are extensively used in rail vehicles to ensure the seamless distribution of electrical power to various components such as traction motors, lighting systems, control systems, and other electrical devices.

Enhancing Reliability and Efficiency

The use of copper busbars in rail systems enhances the overall reliability and efficiency of the power distribution network. Their low impedance and anti-interference properties ensure that power is delivered consistently and without disruption, which is essential for the safe and smooth operation of rail vehicles.

Space-Saving and Easy Installation

Rail vehicles often have limited space, making the compact design of copper busbars particularly beneficial. Their easy installation process further simplifies the construction and maintenance of rail power systems, reducing downtime and operational costs.

Power Distribution in Electric Vehicles (EVs)

Role in Electric Vehicles

Electric vehicles (EVs), including buses and cars, rely heavily on efficient power distribution systems to manage high currents within confined spaces. Laminated copper busbars are used to distribute power between the battery, electric motors, and various electronic components, ensuring optimal performance and efficiency.

Managing High Currents Efficiently

Copper busbars are designed to handle high currents efficiently, which is critical in EV applications. Their low impedance and high current-carrying capacity enable them to manage the substantial power demands of electric motors and other high-power components in EVs.

Compact Design for Confined Spaces

The compact design of copper busbars makes them ideal for the confined spaces found in EVs. This space-saving feature allows for more flexible and efficient layout designs, contributing to the overall performance and reliability of the vehicle.

Power Distribution in Industrial Machinery

Importance in Industrial Applications

Industrial machinery requires robust and reliable power distribution systems to operate efficiently. Laminated busbars are employed in various industrial equipment and machinery to distribute power to motors, control panels, and other electrical components.

High Current-Carrying Capacity

The high current-carrying capacity of copper busbars makes them suitable for demanding industrial applications. Their ability to handle large currents without significant losses ensures that industrial machinery operates at peak efficiency, reducing energy consumption and operational costs.

Durability and Reliability

In industrial settings, durability and reliability are paramount. Copper busbars offer excellent mechanical strength and resistance to environmental factors, making them a dependable choice for industrial power distribution. Their repeatable electrical performance ensures consistent and reliable operation over time.

Power Distribution in Data Centers

Critical Role in Data Centers

Data centers are highly demanding environments that require efficient and reliable power distribution systems. Laminated copper busbars are utilized within server racks and throughout data center facilities to ensure efficient power distribution.

Space Efficiency

Space is at a premium in data centers, making the compact and integrated design of copper busbars particularly valuable. Their ability to save space while providing high power efficiency makes them an ideal choice for data center applications.

Enhancing Operational Efficiency

By utilizing copper busbars, data centers can enhance their overall operational efficiency. The low impedance and high reliability of busbars ensure that servers and other critical equipment receive consistent and uninterrupted power, minimizing the risk of downtime and data loss.

Solutions Provided by Shanghai Wenlida Technology Co., Ltd.

Expertise in Copper Busbar Conductors

Shanghai Wenlida Technology Co., Ltd. is a leading supplier of copper busbar conductors, offering high-quality solutions for various power distribution needs. With a focus on innovation and reliability, the company provides products that meet the stringent requirements of modern electrical systems.

Customized Solutions

Shanghai Wenlida Technology Co., Ltd. offers customized copper busbar solutions tailored to the specific needs of different applications. Whether it’s for rail transportation, electric vehicles, industrial machinery, or data centers, the company delivers products that enhance efficiency and reliability.

Commitment to Quality and Service

With a strong commitment to quality and customer service, Shanghai Wenlida Technology Co., Ltd. ensures that its copper busbar conductors meet the highest standards. The company’s dedication to excellence has earned it a reputation as a trusted partner in the power distribution industry.

Conclusion

Copper Busbar Conductor represents a significant advancement in power distribution technology. Their superior electrical conductivity, compact and integrated structure, and design flexibility make them indispensable in various high-power applications. Shanghai Wenlida Technology Co., Ltd. stands at the forefront of this technology, providing high-quality and customized solutions to meet the evolving needs of modern electrical systems. As the demand for efficient and reliable power distribution continues to grow, laminated copper busbars will play an increasingly vital role in ensuring the seamless operation of electrical systems across diverse industries.