Are Electric Laminated Busbar the Key to Scaling Up Car Production?

Discover the cutting-edge technology of electrical laminated busbars, revolutionizing power distribution in electric vehicles. Explore how laminated busbars offer scalable solutions, enhance sustainability, and drive innovation in electric mobility. Learn more with Wenlida, a leading manufacturer at the forefront of busbar technology.

Boosting Efficiency and Performance: How Laminated Busbars Revolutionize Electric Vehicle Power Distribution

1.1 Introduction to the Role of Laminated Busbars in Electric Vehicles (EVs)

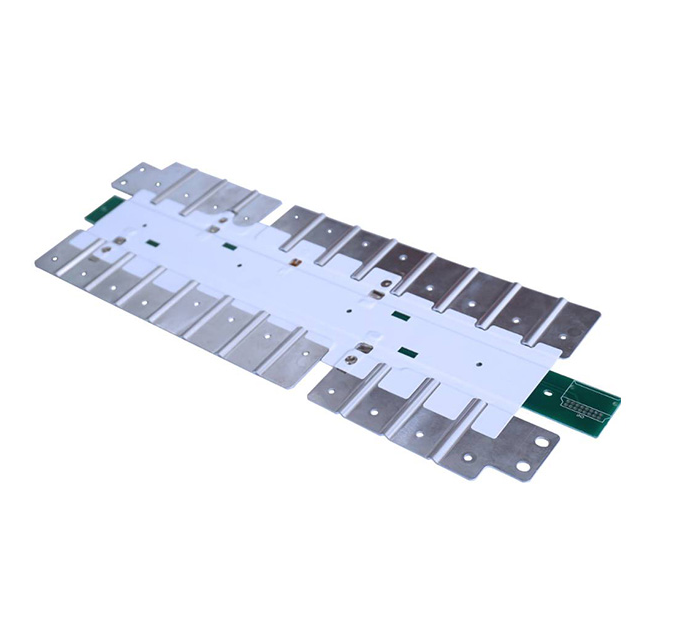

Electric vehicles (EVs) have emerged as a promising solution to combat climate change and reduce reliance on fossil fuels. Central to the functionality of these vehicles is the efficient distribution of power from the battery to various components such as the motor, controller, and auxiliary systems. One key component that plays a crucial role in this power distribution network is the electrical laminated busbar. These innovative conductors have revolutionized the way power is managed within EVs, offering a range of benefits over traditional wiring systems.

1.2 Highlighting the Advantages of Laminated Busbars

In comparison to conventional wiring harnesses, laminated busbars offer several distinct advantages that are particularly well-suited to the demands of electric vehicle applications. Firstly, they significantly reduce weight and occupy less space, enabling manufacturers to maximize interior room for passengers and cargo while also improving overall vehicle performance. Additionally, laminated busbars facilitate more efficient thermal management, helping to dissipate heat generated during operation and ensuring optimal performance of critical components.

Driving Innovation: Customized Laminated Busbars for Electric Vehicle Applications

2.1 Importance of Customized Solutions

In the highly competitive electric vehicle market, customization is key to meeting the diverse needs of consumers and staying ahead of the curve. This holds true not only for the vehicle itself but also for the components that comprise it. Laminated busbars offer a level of flexibility and adaptability that is unmatched by traditional wiring systems, allowing manufacturers to tailor their designs to the unique specifications of each vehicle model.

2.2 Tailoring to Specific Requirements

Laminated busbars can be customized to accommodate a wide range of voltage, current, and space constraints, making them an ideal choice for electric vehicle applications. Whether it’s a compact city car or a high-performance sports model, laminated busbars can be engineered to deliver optimal power distribution while minimizing weight and footprint. This level of customization not only improves overall vehicle efficiency but also enhances the driving experience for consumers.

2.3 Examples of Successful Collaborations

Wenlida has established a reputation for excellence in providing customized laminated busbar solutions for electric vehicle manufacturers. By collaborating closely with EV companies, Wenlida has developed bespoke busbars that meet the exacting requirements of each vehicle model. These collaborations have resulted in improved energy efficiency, extended battery life, and enhanced vehicle performance. By leveraging the expertise of Wenlida’s engineers and the flexibility of laminated busbar technology, EV manufacturers can drive innovation and differentiate their products in the competitive automotive market.

Elevating Safety Standards: Ensuring Reliable Power Distribution in Electric Vehicles with Laminated Busbars

3.1 Exploring the Critical Role of Safety

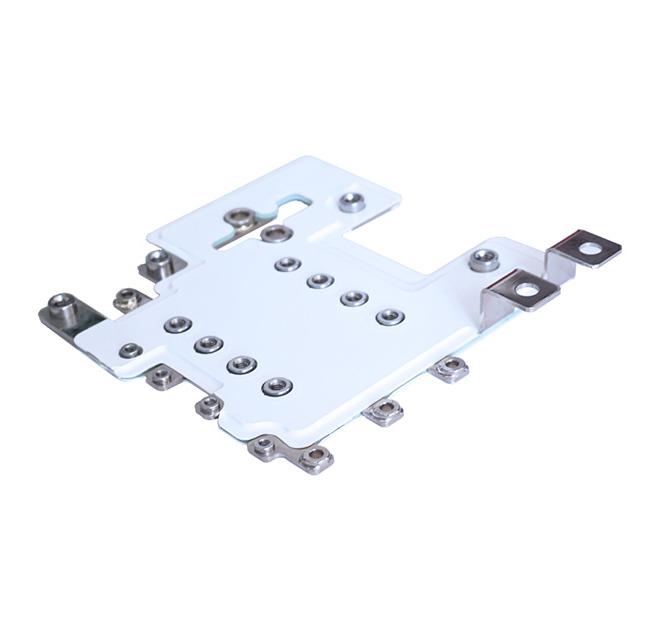

Safety is paramount in electric vehicle design and operation, given the high voltage levels involved and the potential risks associated with electrical faults. Laminated busbars play a crucial role in elevating safety standards within EVs, offering several key features that enhance reliability and mitigate risks. These include improved insulation properties, reduced susceptibility to mechanical damage, and enhanced thermal management capabilities.

3.2 Enhancing Safety Features

Laminated busbars are engineered with multiple layers of insulation, providing superior protection against electrical arcing and short circuits. This helps to minimize the risk of fire or electrocution in the event of a fault, ensuring the safety of both vehicle occupants and bystanders. Additionally, laminated busbars are inherently more robust than traditional wiring harnesses, making them less prone to damage from vibration, shock, or environmental factors.

3.3 Demonstrating Reliability and Safety Benefits

Data and case studies demonstrate the reliability and safety benefits of using laminated busbars in electric vehicle power distribution systems. These studies highlight the significantly lower incidence of electrical faults and system failures compared to vehicles equipped with conventional wiring harnesses. By incorporating laminated busbars into their designs, electric vehicle manufacturers can enhance the safety and reliability of their vehicles, earning the trust and confidence of consumers.

Scaling Up Production: Meeting the Growing Demand for Electric Vehicles with Laminated Busbars

4.1 Addressing the Global Demand for Electric Vehicles

The automotive industry is undergoing a profound transformation as the world shifts towards sustainable transportation solutions. With increasing awareness of environmental issues and government incentives driving adoption, the demand for electric vehicles (EVs) is skyrocketing. However, this surge in demand poses significant challenges for manufacturers in scaling up production to meet market needs. Traditional wiring systems used in EVs can be cumbersome and time-consuming to install, hindering efforts to ramp up production efficiently.

4.2 Highlighting the Scalability of Laminated Busbars

Laminated busbars offer a scalable solution for efficient power distribution in mass-produced electric vehicles. Unlike conventional wiring harnesses, which require intricate assembly and routing of individual wires, laminated busbars streamline the electrical system by consolidating multiple conductors into a single, compact unit. This simplifies the manufacturing process and reduces assembly time, allowing manufacturers to increase production volumes without sacrificing quality or efficiency.

4.3 Discussing Manufacturing Capabilities

Wenlida, a leading manufacturer of electrical laminated busbars, is well-equipped to support large-volume orders from automotive manufacturers. With advanced production equipment and technology. Wenlida has the ability to produce high-quality laminated busbars on a large scale, ensuring on-time delivery to meet customer needs. Through automated production processes and strict quality control measures. Wenlida can guarantee the consistency and reliability of each batch of busbars.

Driving Sustainability: The Environmental Benefits of Laminated Busbars in Electric Vehicles

5.1 Exploring the Environmental Impact of Electric Vehicles

As concerns about climate change continue to escalate, the automotive industry is under pressure to reduce its carbon footprint and adopt sustainable practices. Electric vehicles are a cleaner alternative to traditional internal combustion engine vehicles. They have zero emissions and reduce dependence on fossil fuels. However, the environmental benefits of electric vehicles are not limited to zero-emission operation. They also include the entire life cycle of the vehicle, from manufacturing to end-of-life disposal.

5.2 Highlighting the Role of Laminated Busbars

Laminated busbars reduce material waste, energy consumption and carbon emissions compared to traditional wiring systems. They play a vital role in enhancing the sustainability of electric vehicles. By replacing bulky wiring harnesses with streamlined busbars, manufacturers can optimize space utilization within the vehicle, reduce overall weight and improve energy efficiency. This can extend the driving range per charge and reduce energy consumption during operation. This further reduces the environmental impact of electric vehicles.

5.3 Showcasing Certifications and Eco-Friendly Initiatives

Wenlida is committed to sustainability and environmental stewardship in its manufacturing processes. The company holds certifications for compliance with international environmental standards and continuously seeks ways to minimize its ecological footprint. From sourcing materials responsibly to implementing energy-efficient production methods, Wenlida strives to align with the sustainability goals of automotive manufacturers and contribute to a greener, more sustainable future for transportation.

Future-Proofing Electric Vehicles: Innovations in Laminated Busbar Technology

6.1 Exploring Ongoing Advancements

The rapid pace of technological innovation is driving continuous advancements in laminated busbar technology, paving the way for future-proof electric vehicles. One of the key trends in busbar design is the pursuit of higher power densities, allowing for more compact and efficient power distribution solutions. This enables electric vehicle manufacturers to maximize space utilization and optimize vehicle performance without compromising safety or reliability.

6.2 Integration of Smart Features

Another emerging trend in laminated busbar technology is the integration of smart features for enhanced functionality and connectivity. By incorporating sensors, communication modules, and diagnostic capabilities into the busbar design, manufacturers can monitor the health and performance of the electrical system in real-time, enabling predictive maintenance and optimizing vehicle uptime. This proactive approach to maintenance not only improves reliability but also reduces operational costs for fleet operators.

6.3 Collaborating for Innovation

Wenlida sincerely invites automobile manufacturers to cooperate in the development of innovative laminated busbar solutions. Shaping the future of electric mobility. By working together to identify emerging needs and challenges, Wenlida can draw on its expertise in busbar technology. Create customized solutions that meet the unique needs of each vehicle platform. By embracing innovation and collaboration, automakers can stay at the forefront of EV technology. And stand out in the fiercely competitive market environment.

Conclusion

In conclusion, electrical laminated busbars represent a game-changing technology that is driving innovation and elevating safety standards in the electric vehicle industry. Laminated busbars offer the ability to increase efficiency, enable customization and enhance safety. It is expected to play a central role in the continued development of electric vehicles. Collaborations between laminated busbar manufacturers, such as Wenlida, and electric vehicle companies are driving progress. and pave the way for a cleaner, more sustainable future in transportation.