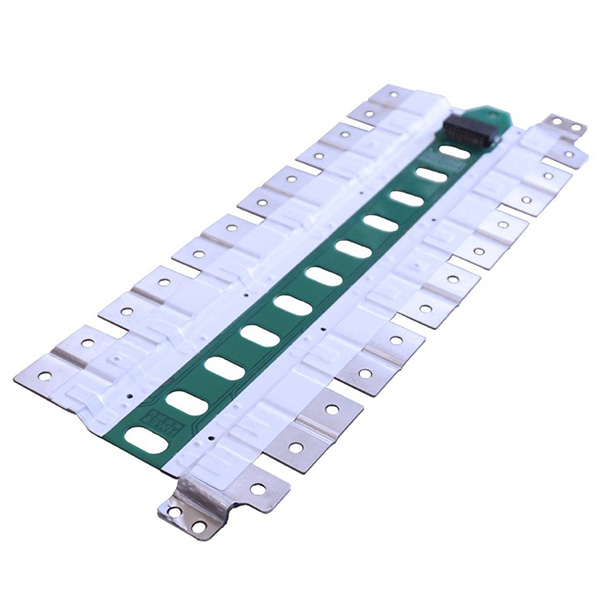

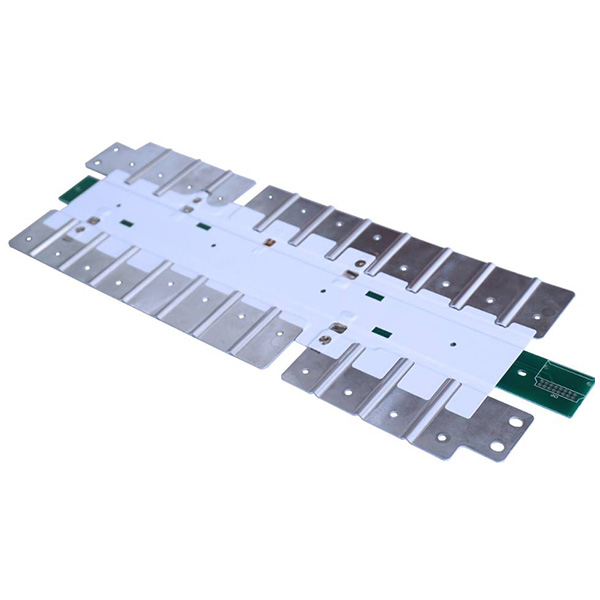

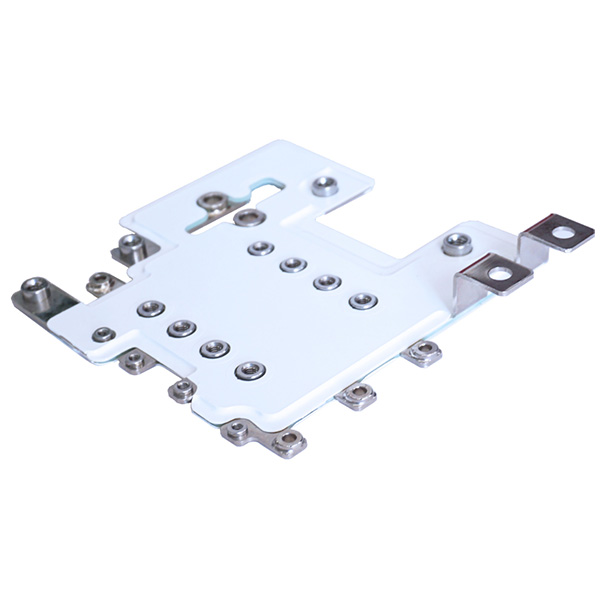

Laminated Busbar for Electric Car / Automative

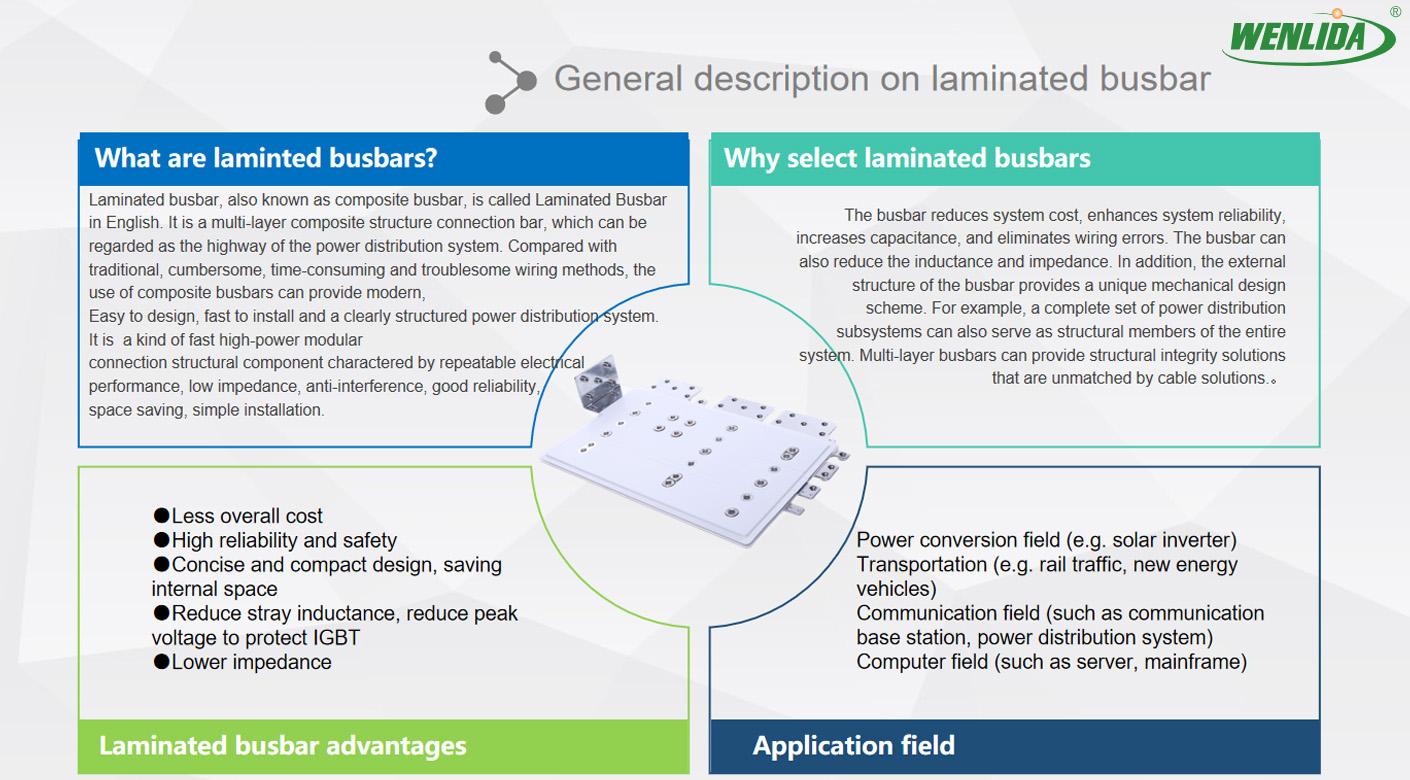

A laminated busbar for an electric car refers to a component used in the electrical system of the vehicle. A busbar is a metallic strip or bar that conducts electricity within a system. It serves as a central point for the distribution of electrical power to various components, such as batteries, motors, and other electronic devices. In the context of an electric car, a laminated busbar is designed to efficiently and safely distribute electrical power within the vehicle's electrical system. It can handle the high currents and voltages associated with electric vehicle powertrains. The laminated construction helps manage heat dissipation, reduces electrical losses, and provides a compact and lightweight solution.

- Insulation resistance:20M Ω DC/1000V

- Parasitic inductance:15nH/m

- Temperature rise:≤30K

- Working temperature:-40~105℃

Product Description

Advantages

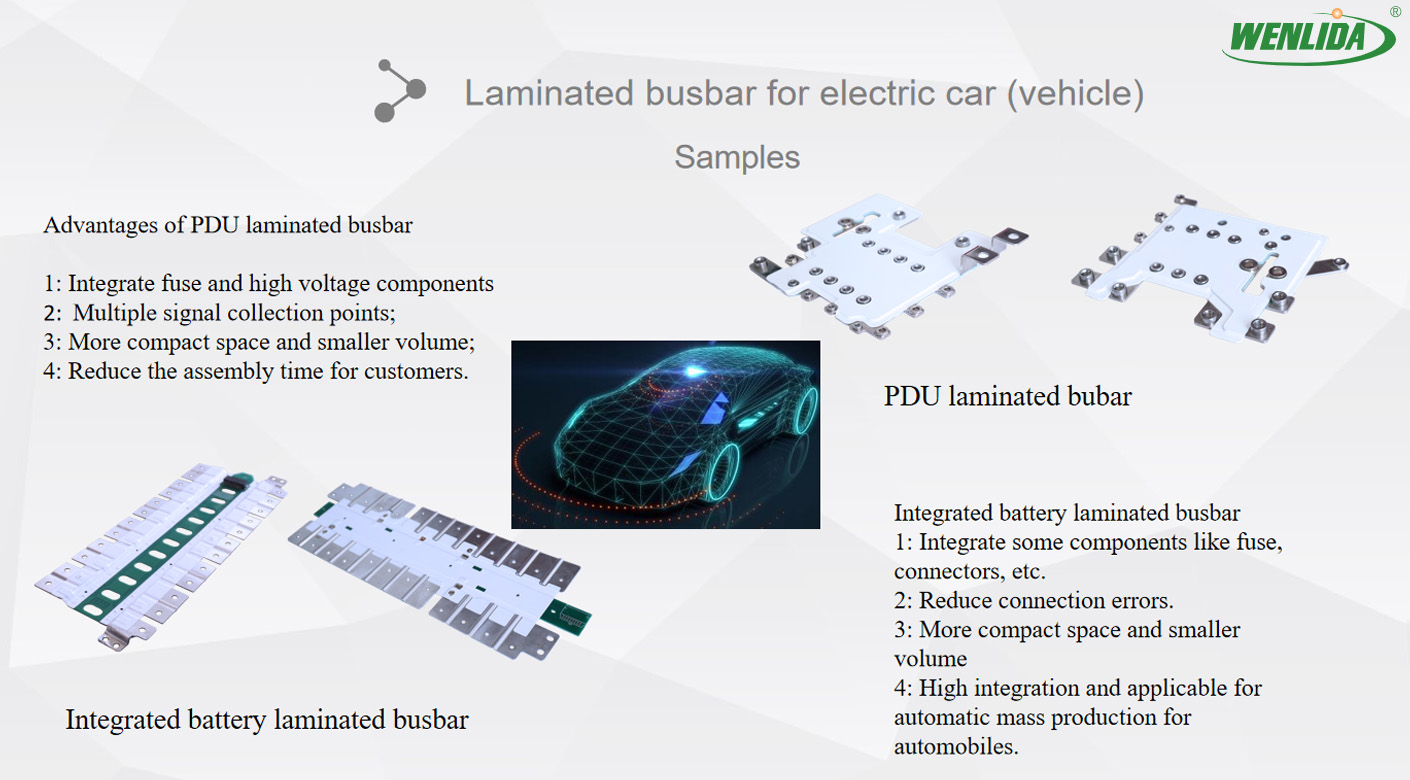

- Integrated Components: Our Laminated Busbar combines fuses and connectors within its structure, simplifying assembly and boosting electrical system efficiency.

- Error-Reducing Design: Precision integration minimizes connection errors, ensuring a reliable and mistake-resistant electrical system.

- Compact Form Factor: With a smaller volume, our busbar optimizes space within electric vehicles without compromising performance.

- Minimized Welding and Assembly: Streamlined manufacturing reduces welding and assembly needs, offering a cost-effective and straightforward production process.

- High Integration for Mass Production: Designed for automation, our Laminated Busbar excels in high integration, facilitating efficient and consistent mass production for electric cars.

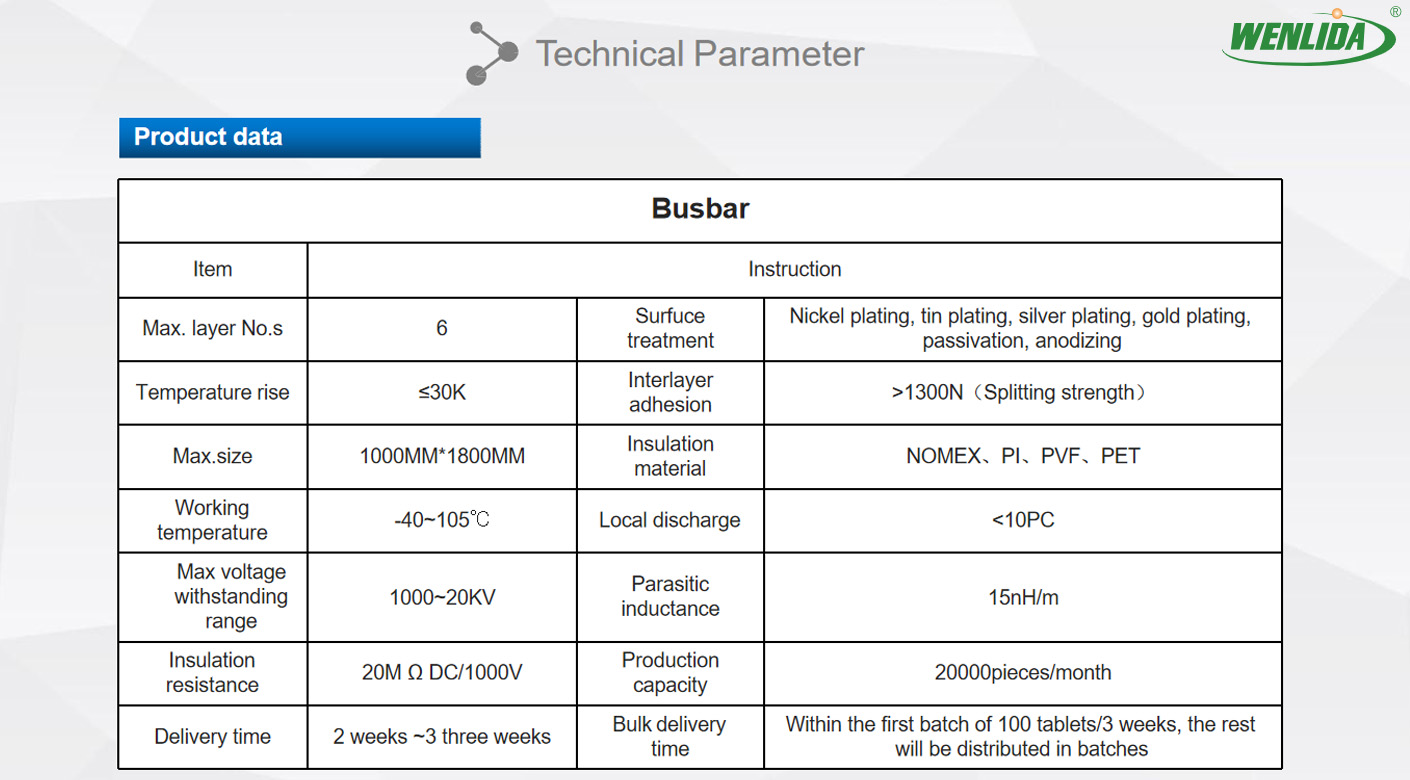

Technical Parameter

Product Data

| Busbar | |||

| Item | Instruction | ||

| Max. layer No.s | 6 | Surfuce treatment | Nickel plating, tin plating, silver plating, gold plating, passivation, anodizing |

| Temperature rise | ≤30K | Interlayer adhesion | >1300N (Splitting strength) |

| Max. size | 1000MM*1800MM | Insulation material | NOMEX、PI、PVF、PET |

| Working temperature | -40~105℃ | Local discharge | <10PC |

| Max voltage withstanding range | 1000~20KV | Parasitic inductance | 15nH/m |

| Insulation resistance | 20M Ω DC/1000V | Production capacity | 20000pieces/month |

| Delivery time | 2 weeks ~3 three weeks | Bulk delivery time | Within the first batch of 100 tablets / 3 weeks, the rest will be distributed in batches |

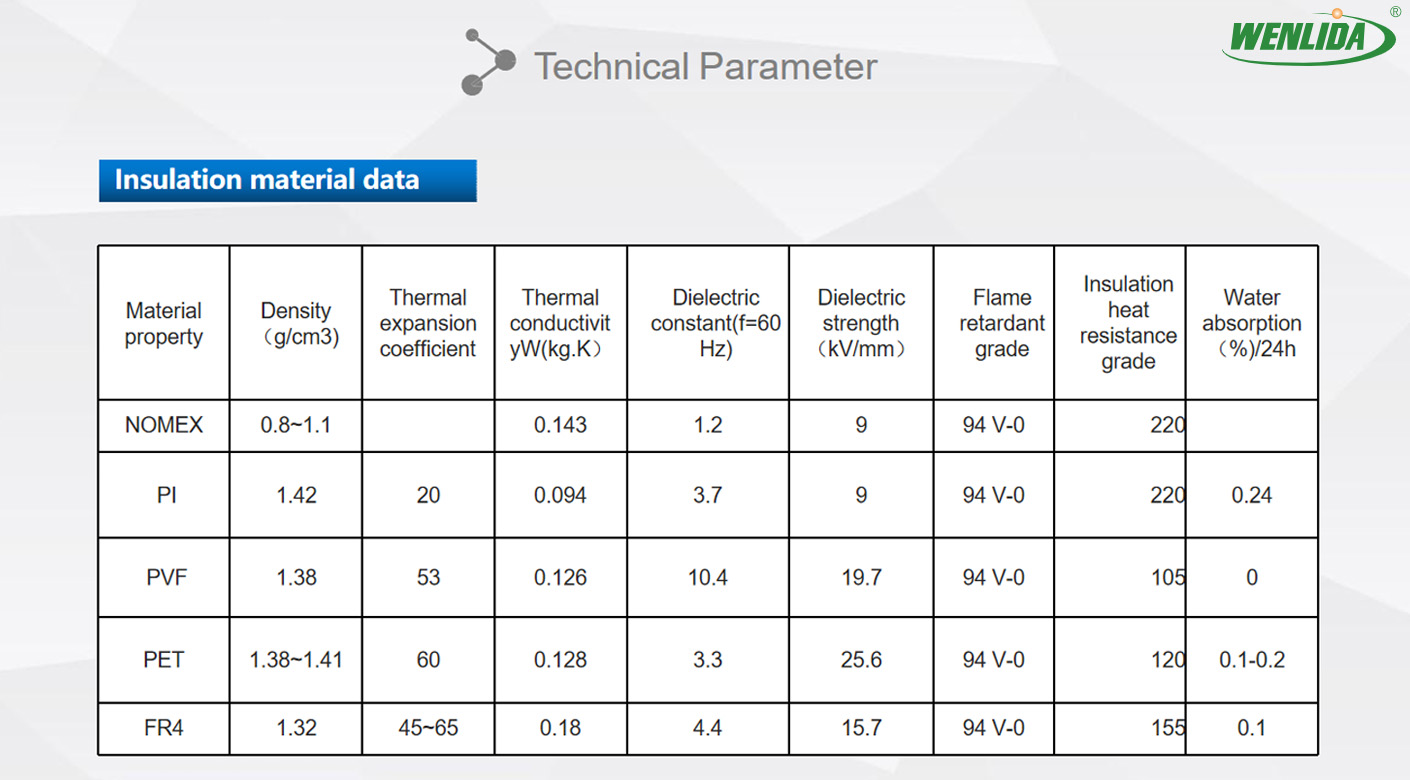

Insulation material data

| Material property | Density (g/cm3) | Thermal expansion coefficient | Thermal conductivity yW (kg. K) | Dielectric constant (f=60 Hz) | Dielectric strength (kV/mm) | Flame retardant grade | Insulation heat resistance grade | Water absorption (%)/24h |

| NOMEX | 0.8~1.1 | 0.143 | 1.2 | 9 | 94 V-0 | 220 | ||

| PI | 1.42 | 20 | 0.094 | 3.7 | 9 | 94 V-0 | 220 | 0.24 |

| PVF | 1.38 | 53 | 0.126 | 10.4 | 19.7 | 94 V-0 | 105 | 0 |

| PET | 1.38~1.41 | 60 | 0.128 | 3.3 | 25.6 | 94 V-0 | 120 | 0.1-0.2 |

| FR4 | 1.32 | 45~65 | 0.18 | 4.4 | 15.7 | 94 V-0 | 155 | 0.1 |

Application Fields

- Battery Management System (BMS):

- The busbar is integrated into the BMS to efficiently distribute power among the battery cells.

- Streamlining connections within the BMS, it aids in precise monitoring and control of individual cells.

- Power Electronics:

- In the power electronics system, the busbar plays a crucial role in distributing power between the inverter, converter, and other components.

- Integration of components within the busbar reduces space requirements and simplifies the assembly process.

- Charging Systems:

- Within the electric vehicle charging system, the laminated busbar facilitates efficient power distribution during charging processes.

- Compact design and integrated components contribute to streamlined connections in charging infrastructure.

- Electric Motors:

- The busbar is employed in the power distribution network for electric motors, ensuring optimal performance.

- Its design minimizes errors and contributes to a more reliable electrical system in the motor assembly.

Recommend

Now, let your business to a higher level, start professional consultation!

*We Will Reply To You Within 24 hours. Our working days are Mon.to Sat., 9:00 ~ 18:00.